Reduce, reuse, recycle. Like brushing your teeth after a meal, recycling is just the right thing to do.

But now that China has stopped taking our trash, we’re scrambling to figure out how to keep all those good intentions out of the landfill.

Chemical engineering Professor Sankar Bhattacharya says there’s a silver lining. To him, it’s an opportunity for Monash to take a leading role in solving the problem at home.

Professsor Bhattacharya has built a prototype processing plant on campus that turns plastic, as well as waste tyres, into diesel fuel.

“The majority of the plastics we use in our daily life – different grades of polyethylene, polypropylene, polystyrene and even polyvinyl chloride, to some extent – can be processed into liquid fuel,” he says.

That’s what China was doing with the plastic recyclables it bought from us, he explains. “They’re now realising that their domestic production of waste products is so large that they cannot process any more by bringing in waste plastics from other countries.”

Time is of the essence, he says; the Chinese embargo means that everything we sold to them has to find another home – and right now, that’s the landfill. Once plastic is there, it’s there to stay. Research suggests grocery bags could take anywhere from 500 to 1000 years to degrade – not exactly a shining legacy to leave for future generations.

The numbers are staggering. Australians produce more than 43 million tonnes of solid waste a year. Every day we use more than 10 million plastic bags. In 2015-16, Victoria collected nearly 600,000 tonnes of recyclables, of which 9 per cent was plastic containers.

A green scene

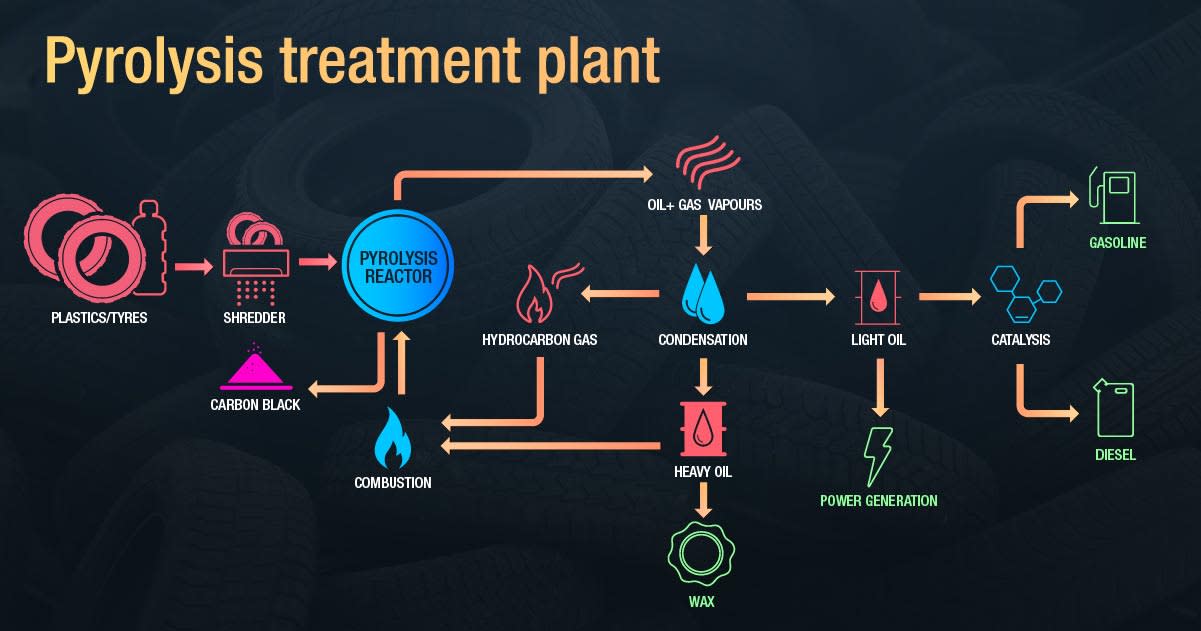

Turning plastic back into fuel might not seem environmentally friendly, but in reality it’s about as green as it gets. When heavy crude oil is processed, the stuff that remains in the bottom-most fraction after producing jet fuel and transportation fuel are the ingredients for making plastic.

So recycling plastic into fuel brings things full circle. In a perfect world, recycling plastic into fuel would result in less oil extraction to begin with.

It’s not all rainbows and unicorns, of course. The high-temperature catalytic process operates at temperatures around 400 degrees Celsius, and this requires energy input. Sorting and cleaning the waste gobbles water. The gaseous emissions produced as a by-product include carbon dioxide.

But this isn’t as awful as it sounds, says Professor Bhattacharya. “Some of the really combustible gases that will be produced during the processing of the waste plastics are effectively recycled back to sustain the process.”

Other, greener-sounding plastic recycling solutions – transforming recycled plastic into solid objects such as playground equipment, chairs or fleece, for example – are great and will have small niche market, but they ultimately postpone the problem, he says. “These things also have a shelf life, and at some point the question of recycling them will arise again, or else these will go to landfill.”

Read more: New approaches to forsaken food

Professor Bhattacharya, who came to Monash after a long career commissioning coal-fired power plants and gasification plants, is determined to translate this technology into one or more full-scale processing plants that can start taking recyclables as soon as possible. And to do this, he’s starting close to home.

He’s entered into discussions with three councils that border the University to scale up his laboratory processing facility into a plant that can handle real-world waste streams. His team has collected statistics on the volume of waste generated by the councils. “It’s definitely possible to build three 10-tonne-per-day or one 30-tonne-per-day plant on the land which is owned by any one of the three councils,” he says.

“The majority of the plastics we use in our daily life ... can be processed into liquid fuel.”

He and his team have built a business case to obtain venture capital funding. “We did a generalised techno-economic analysis, including the capital costs of such a plant, all the control systems that will be necessary to run it, the manpower for three shifts on a day in, day out basis, the purchase of the feedstock supply,” he says. “Within two to five years, depending on the initial price of the plant that will be built, it will have a net positive value.”

In addition to plastics, the developed technology can also be tweaked to process waste tyres into fuel. Tyres are a huge waste issue in Australia; for example, in 2013-2014, 51 million equivalent passenger units (1EPU = 8kg) of tyres ended up in the waste stream. According to the latest report, only 5 per cent of these are recycled locally, the rest going to landfill, stockpile and illegal dumping. Professor Bhattacharya’s team has collaborated with industry on processing of waste tyres to fuel, and electronic waste for high-value metal recovery using non-toxic ingredients.

A win-win for all

Processing plastic and tyre waste into fuel at home would be an environmental win-win for Australia. Not only could we keep these items out of the landfill, but we could also at the same time reduce our dependence on extracted and imported fossil fuels.

“We have the opportunity here to showcase our capacity and expertise in the processing of waste tyres as well as waste plastics – right now. We can scale them up easily,” he says.

And when he says easily, he means it. “If everything falls into place, we start the work and within one year we have a plant built here – subject, of course, to EPA approval, land availability and all those kinds of things. But, really, it can be done that quickly.”

So go right ahead and keep recycling until the use of "biodegradable" plastics becomes widespread. It's the right thing to do.

Find out more about this topic and study opportunities at the Graduate Study Expo