At this moment, thousands of researchers globally are working to develop vaccines and other treatments for COVID-19 to save millions of lives.

Ideally, this is how we should confront challenges – as a global community. When the problem is urgent, pursuing a range of options is the most efficient way to ensure we find a combination of solutions that works.

Climate change is an equally urgent problem, with more than 100 countries declaring climate emergencies.

While we rapidly transition from one energy source (coal) to a better option (gas), we also need to be developing cleaner, sustainable, renewable energy sources, such as wind and solar.

But it’s not an “either/or” proposition as is often debated in research and media circles. We can do both.

Coal seam gas extraction has had its share of detractors. The current practices of coal-bed methane recovery cause immense damage to groundwater resources, as millions of gallons of water is being pumped from the ground to displace the methane. This contaminated water is then stored in open ponds.

The way forward with geothermal energy

But, the lessons from pursuing coal seam gas are already helping us understand and improve on a form of renewable energy also found deep underground – geothermal energy.

In fact, geothermal energy – which I call a “renewable deep-earth energy battery” – is much cleaner than any other form of renewable energy.

Every engineering project carries practical challenges, but if we can overcome these, we can transform the coal seam gas industry into an environmentally sustainable energy source. That’s worth considering as part of our transition from coal.

How does coal seam gas extraction work?

Coal seam gas is a natural gas found in coal deposits, hundreds of metres underground. When coal is formed, large quantities of gas are stored within it.

The gas is held in place by water pressure. To extract it, wells are drilled through the coal seams, reducing water pressure and releasing natural gas from the coal. The gas and water are separated, and the gas is piped to compression plants for transportation.

Extracting gas (and many other underground resources, including rare earth minerals, metals, unconventional, tight, or shale gas, renewable energy) is more effective if you first fracture the rock in which the gas/minerals is trapped.

Hydraulic fracturing (fracking) is the existing method for breaking rocks deep underground, but due to serious environmental concerns it’s been banned or moratoriums are in place in many parts of Australia, including in Victoria, and overseas.

The major problems with fracking are largely due to the explosive energy it uses to break the rock. It’s uncontrolled, which means operators can’t be sure exactly where the fractures will go. They might break into and contaminate groundwater reservoirs; they may also activate faults that can induce seismic activity.

We simply can’t carry out the same mining methods that have been employed over the past few centuries.

The Australian mining industry currently uses about 5-7% of the nation’s total electricity supply for crushing and grinding rocks to liberate minerals. This is enormous energy consumption, and it also leaves a vast amount of waste rock (mine tailings) in tailing dams, which is another environmental disaster.

A 2019 UN Global Resources Outlook report shows mining and hydrocarbon resources contribute about 26% of total CO₂ emissions (nine billion tonnes of CO₂). This is just during the extraction and processing phases.

That said, improving gas extraction processes can help us rapidly transition to cleaner energy in the shorter term, while also providing scientific insights for developing renewable energy sources.

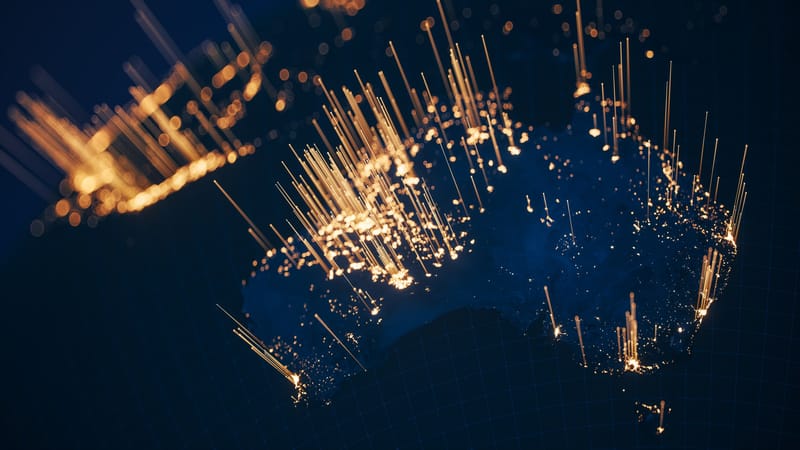

Why should Australia continue with gas extraction?

Developing ways to break rock where it sits underground has such huge potential, because then we don’t have to dig ore out of the ground, haul it to a crushing site, and process it to release the trapped minerals.

Instead, by pumping extraction fluid through the fractured rock where it sits, the minerals are released and brought to the surface at the site.

Think about how much energy it takes to move heavy rock. By leaving it in situ, we can save massive amounts of energy, and no waste rock to store in dams, which can occasionally lead to catastrophic failures such as the Brazil tailings dam disaster in 2015.

Reducing the industry's carbon footprint

My recommendations for Australia to reduce the resource industry’s carbon footprint are:

- Develop rock-breaking technologies that use less energy.

- Create a circular economy that turns resource industry waste into wealth.

- Develop renewable energy sources, such as what I earlier called “renewable deep-earth energy batteries” (geothermal).

Australia needs to find ways to turn waste into products.

For example, my team has been able to capture fly ash from coal power stations and use it (and CO₂) to create an environmentally-friendly, high-yield agricultural fertiliser.

The more we can recycle and reuse these waste products, the better off we’ll be while we wait for the development of cleaner technologies.

The reason for my third recommendation is simple – even solar and wind power are not carbon-zero.

Many of the key materials used to build solar panels and wind turbines come from the ground, consuming sources of energy that emit CO₂. And, when the panels and turbines reach the end of their usable life, we’re left with further waste.

Solar and wind are obviously a critical part of the energy transition, but completely renewable energy (such as geothermal) needs to be our ultimate goal.

How have we changed it?

Our research team has been using a fluid form of carbon dioxide (supercritical CO₂) to sweep methane from the coal seam for extraction, while leaving some of the CO₂ behind, stored safely in the coal.

This approach has two advantages. It delivers a more energy-efficient fuel (methane compared to coal), and it stores unwanted CO₂ securely underground – compensating for some of the CO₂ emitted while using this energy source.

Our breakthrough SREMA – slow-releasing material agent (patent pending) – approach is a world-first in that it’s non-explosive and uses very little water.

The process is simple. Various environmentally-friendly ingredients are mixed with water to make a thin slurry. This is injected into rock, and slowly expands as it sets, thus non-explosively breaking the rock.

Not only does this avoid contaminating groundwater, inducing seismic activity, or consuming precious water supplies, but it produces better fracture networks that yield resources far more efficiently.

Read more: Rehabilitation opportunities: How Victoria can repurpose its abandoned mines

Controlled fractures mean more efficient complex fracture networks – it’s good for the environment, and the bottom line.

This innovative approach can break rocks on the surface, at depth (several kilometres deep), under water, or under heat. It has many applications, including in mineral/metal extraction, hydrocarbon (oil/gas) extraction, and geothermal energy extraction.

By replacing hydro-fracking with SREMA, we can significantly increase the recovery rate of hydrocarbon and mineral resources from reserves deep down, greatly boosting the economic benefits while reducing the environmental damage.

We need to develop a wide range of global options for an effective, rapid transition to more renewable energy sources.

Gas certainly holds potential, but we can’t focus on it at the expense of developing other cleaner-energy technologies. We must work on all potential strategies for decarbonising the economy.