Australia has certainly demonstrated its appetite for solar power. With the average lifespan of a solar panel being approximately 20 years, many installations from the early 2000s are set to reach the end of their lives imminently.

The question is, will they end up in landfill, or be recycled?

The cost of recycling is higher than landfill, and the value of recovered materials is smaller than the original, so there’s limited interest in recycling. Given the presence of heavy metals, such as lead and tin, if waste is managed poorly, we’re on track for another recycling crisis.

A potential time bomb could present itself as an opportunity, however, if the global electric vehicle (EV) industry showed an interest in the recovered solar products.

The presence of hazardous materials in the end-of-life panels can result in significant pollution and health issues, if released into the environment.

The main contributor to the total weight of a typical crystalline silicon PV module is glass by 75 per cent, followed by 10 per cent polymer, 8 per cent aluminium, 5 per cent silicon (the solar cells), 1 per cent copper, and small amounts of silver, tin, lead, and other metals and components.

Lead and tin, if leached into soil and groundwater, cause health and environmental concerns, while copper, silver and silicon present a value opportunity if recovered efficiently.

Among the valuable materials in the panel, silicon presents the best opportunity, given its considerably larger fraction and its ultra-high purity (99.9999 per cent). The solar-grade silicon from PV waste can be recovered for second-use applications in solar panels, or can be repurposed for value-added application in the anode of lithium-ion batteries.

One industry's trash could be another industry's treasure

The ever-growing number of electric vehicles presents a unique opportunity to the materials recycling world and waste management industry. And there may be room for used solar panels, too.

Read more In search of battery-grade silicon

Today’s EV batteries are an essential part of the total EV cost (33 per cent to 57 per cent, depending on the car), and materials production is the dominant contributor to the energy cost of making the batteries. So, cost-cutting strategies rely heavily on innovations at the materials level – raw materials sourcing and processing.

While EV fans definitely welcome lower prices, setting mileage records is what makes headlines. In 2015, Tesla’s Elon Musk claimed that silicon in Model S batteries increased a car's range by 6 per cent. Since then, EV companies such as Daimler and BMW have also been actively engaged in research and development programs to synthesise battery-grade silicon for EV application, and silicon recovered from the solar panel may just be what they need.

Supplying critical battery materials

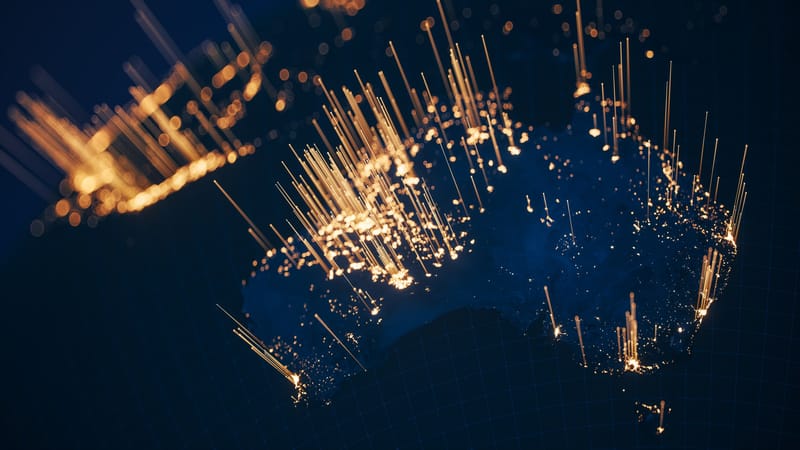

Australia has always been well-placed among the fast-expanding PV markets such as China, Japan, India, and the US, and now, with more than 2.3 million rooftop solar power systems installed across the country, we officially rank first.

But, the recycling of end-of-life PV modules is not regulated in Australia. In fact, Europe is the only region that has a robust and transparent regulatory framework to support the PV recycling process. The Waste Electrical and Electronic Equipment Directive (WEEE Directive) mandates European countries to adopt PV waste management programs, where producers are responsible for the take-back and recycling of the panels they sell.

Read more: Batteries made with sulfur could be cheaper, greener and hold more energy

The goal of these policies is to develop greener products, and make recycling more affordable and economically sustainable by leading producers to factor in the cost of the collection and end-of-life treatment of their products into the price paid by the consumers.

A national program, led by Sustainability Victoria, is hoping to change this. The goal is to make recommendations to state, territory, and federal governments on a preferred national management approach.

It's expected that more than 100,000 tonnes of solar panels will enter Australia’s waste stream by 2035.

Is this a crisis or an opportunity?

If you look up solar panel recycling in Australia, there are some services. However, mostly they can recycle less than 20 per cent by weight – the aluminium frame and the terminal boxes. Recycling the remaining 80 per cent, including the precious silicon, is not offered in Australia.

But, it doesn't have to stay that way.

You can only do what you can sell

While as users we can’t do much but to rely on responsible recycling businesses to dispose of the solar panels' waste properly, as scientists and engineers we may be able to do more. Providing scientific evidence on the potential impacts and benefits of recycling PV panels could incentivise the government and industry to change its policy settings.

Our collaborative study with The Group of Research in Energy and Environment from Materials (The GREENMAT) at the University of Liege in Belgium provides such evidence. Evidence that in the future, end-of-life solar panels may prove to be a valuable secondary resource for a critical material in electric-vehicle batteries: ultra-pure nano-structured silicon.

The process of recycling silicon modules in Europe began more than a decade ago. However, the problem associated with most processes developed to date is that the recovery rate is not more than 80 per cent, and the value of the retrieved materials isn't competitive compared to the originals.

GREENMAT, alongside other academic and industrial partners, has been involved in SOLARCYCLE – a project supported by the Wallonia region in Belgium, which investigates economic recycling solutions that can achieve a recovery rate of at least 95 per cent.

As part of this program, GREENMAT patented a greener, more cost-effective method of dismantling the PV modules; namely by avoiding the high temperatures (450-600°C) usually employed for burning the materials. GREENMAT’s hydrothermal recycling method, which is conducted at temperatures below 200°C, prevents the combustion of halogenated polymers, and the vaporisation of heavy metals such as tin, lead, and silver; hence avoiding the waste gas treatment step.

Just as importantly, the use of moderate temperatures prevented the melting and diffusing of metallic contacts components into other photovoltaic components, such as glass and silicon wafers, which bypass purification steps necessary for the recovery of high-purity silicon and glass.

The simple and scalable dismantling process was tested on several PV brands, and offered clean glass, which was made available to relevant industries to evaluate the value of the recovered material.

In a follow up project, ultra-pure silicon (99.99 per cent) was recovered by using critically-tuned alkali-acid leaching baths, in the absence of the commonly used corrosive hydrofluoric acid.

The considerably greener method effectively removed the major impurities, including lead, silver, and aluminium. The ultra-pure silicon was then nano-sized via industrially-scalable milling routes to meet the requirements of expansion-tolerant silicon anodes for lithium-ion batteries.

We're excited about our latest discovery, published in the Journal of ACS Sustainable Chemistry and Engineering, which reports the simple and economic recovery of nano-structured silicon from end-of-life PV panels with demonstrated value-added applications in lithium-ion batteries.

Here at Monash University, the lithium-sulfur battery team and I are even more excited, as we believe that in addition to lithium-ion batteries, lithiated silicon-based anodes may also find application as alternatives for the highly reactive lithium metal in lithium-sulfur batteries.

In the ABC’s Utopia, Rob Sitch showed us how marketing becomes central to a utopian dream because “you can only do what you can sell”. As scientists, we cannot do much marketing, but we can provide evidence that if you recycle properly, you can sell.