Engineers from Monash University are flipping the script on how we source critical metals. Instead of digging deeper into the Earth, they’re turning to the unlikeliest of places – coal fly ash, the powdery waste left behind by burning brown coal.

For decades, Australia’s coal-fired power stations have produced millions of tonnes of this ash, most of which ends up in ash dams or landfills. It’s long been seen as a waste management headache.

But what if that so-called waste could help power the technologies of the future – and ease the pressure on traditional mining?

Rare earth elements – or REEs – are critical ingredients in electric vehicles, wind turbines, smartphones and defence systems. But they’re not easy to get. Right now, most of the world’s supply, about 90% of global refining, comes from one country. That makes prices volatile and supply uncertain.

Australia does have known deposits of rare earths, and there are several projects underway to mine and process them. But opening a new mine can take 10 to 15 years, involves high capital costs, and comes with significant environmental and social concerns, particularly when it comes to water use, land rehabilitation, and community impact.

So we found a better way.

From old comes new

We’ve developed a cleaner, more efficient way to extract rare earths from coal fly ash, mine tailings and even old electronics. It’s called urban mining – recovering valuable materials from things we’ve already used, instead of digging for more.

Our method can recover all 17 rare earth elements with more than 90% efficiency. That includes the highly sought-after “magne” rare earths such as neodymium and dysprosium, which are key to making the powerful magnets found in electric motors and wind turbines.

One of the major advantages of our approach is that coal fly ash, especially the kind produced from brown coal in Victoria, typically does not contain radioactive elements such as thorium or uranium.

This makes the extraction process inherently safer, less regulated, and more environmentally sustainable than conventional rare earth mining.

To give you a sense of the potential, from coal fly ash alone, we could recover up to 45,000 tonnes of rare earth metal each year.

That’s more than twice what Australia produced in 2021, and nearly 30% of current global production. That amount of rare earth metal is enough to make the magnets needed for about 15 million electric vehicles.

Waste as a resource

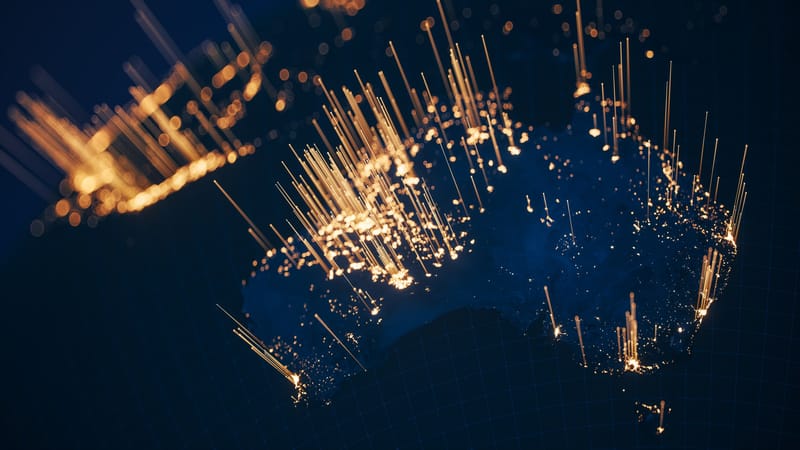

And this isn’t a far-off dream. In Victoria alone, more than a million tonnes of fly ash are generated annually. Nationally, the stockpiles are even larger.

By treating these stockpiles as a resource, not waste, we can make immediate use of existing materials while avoiding the environmental footprint of new mining.

We’ve already scaled up our process from a small lab setup to a 30-litre system, and we’re now designing a 100-litre semi-continuous unit, with a demonstration plant planned at Monash University. The technology has already won awards, and we’re ready to take the next step.

This is more than a technological breakthrough – it’s an opportunity to reshape how Australia thinks about resources.

A world-leading opportunity

Urban mining could support local manufacturing, reduce our dependence on foreign supply chains, and create jobs in regional communities. It also allows us to clean up legacy waste from coal-fired power generation in the process.

Urban mining gives Australia a chance to lead the world in clean, homegrown rare earth supply while also solving a legacy waste problem. It could create regional jobs, support local manufacturing, and reduce our reliance on overseas supply chains. It’s a rare opportunity.

And we don’t have to mine it, just rethink it.

Right now, we’re working with industry and government partners to bring this to market. With the right support, we can build a circular, more resilient supply chain for Australia’s future – and do it by unlocking value from what we already have.

We don’t need to dig deeper into the earth to find the metals of the future. We just need to look at what we’ve already got, and think differently about how we use it.