When Monash chemistry Professor Doug MacFarlane was a PhD student at Purdue University in Indiana, he worked on “liquid salts” for use in preserving living tissue – including human kidneys and marine corals. Fast-forward 30 years and marine biologists are now freezing hundreds of species of corals threatened by global warming in these salts, which are also known as ionic liquids.

Professor MacFarlane’s focus, as a researcher, has been to explore the many useful things that ionic liquids can do. This new class of chemicals is also now being used to create renewable fuel and fertiliser, and ‘green’ chemical solvents.

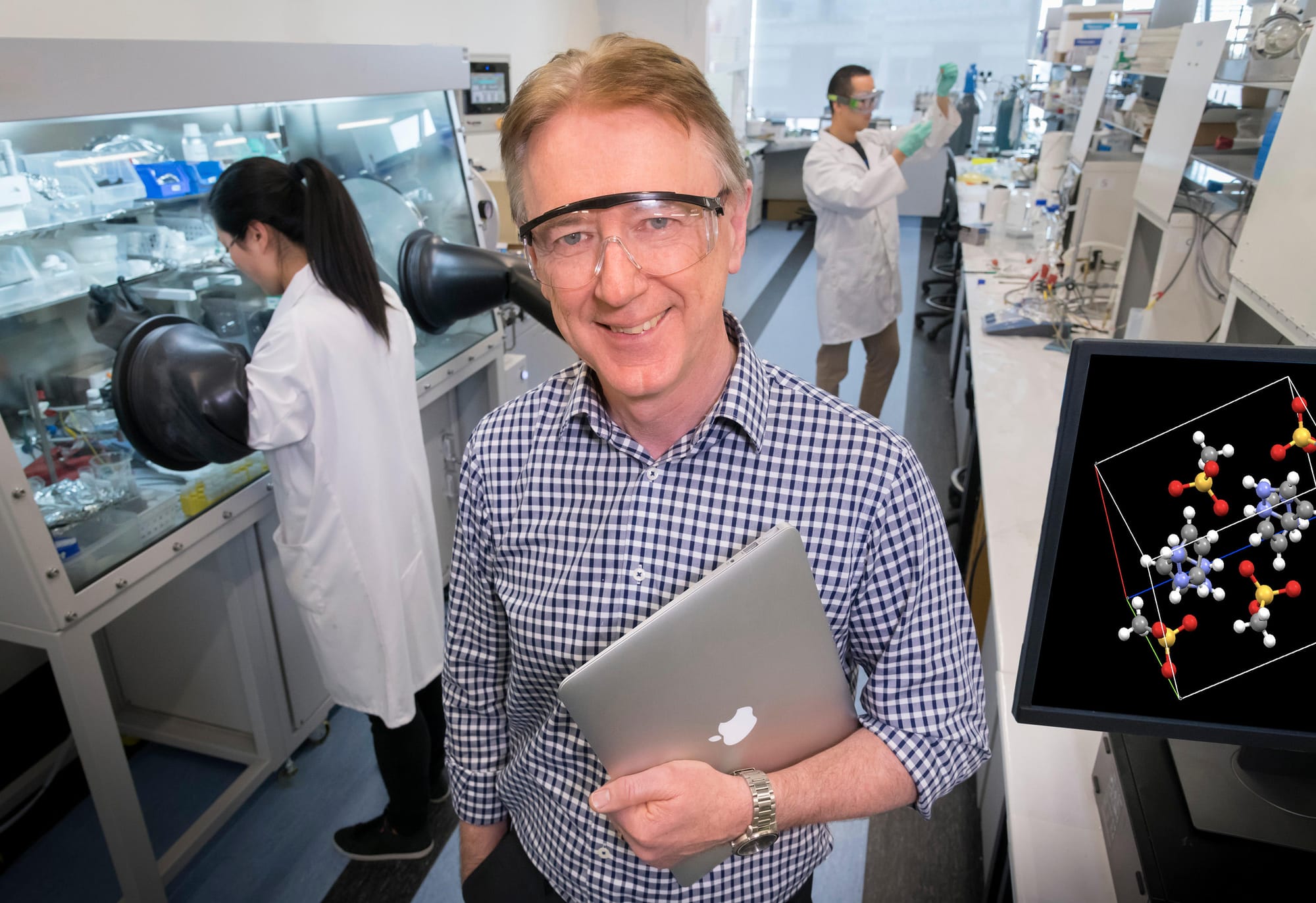

For his pioneering work with ionic liquids, Professor MacFarlane has been awarded the 2018 David Craig Medal, the Australian Academy of Science’s most senior prize for research in chemistry.

“I was working on these as a PhD student 30 years ago, and we had these systems that were liquid at room temperature and almost all salt, and we didn’t think terribly much about it,” he recalls.

“It was a discovery, but a non-discovery in a sense because we didn’t know their significance.”

A few years later, he and a number of other people around the world began to realise that liquid salts were “interesting solvents –– for electrochemistry, for green chemistry – and people began to search for systems that had these properties”. Thousands of liquid salts have since been identified, he says, “but potentially millions exist”.

Asked to name the most important use of liquid salts, Professor MacFarlane nominates the development of artificial photosynthesis, which has given birth to the Monash Ammonia Project. (Artificial photosynthesis mimics how plants convert sunlight into energy and chemicals, a goal of renewable energy research.)

“What we have discovered is that some of these ionic liquids are very, very effective in allowing us to produce ammonia from the nitrogen around us, using renewable electricity,” he explains. Ammonia is the source of most fertilisers, and making it sustainable is a major global challenge. It could also be used in the future as a sustainable fuel source.

Professor MacFarlane predicts that within a decade sustainable ammonia “can become Australia’s big, future energy export”. Monash is “in a world-leading position,” he says. “We are about to form a spin-off company to explore this.”

The economic potential is huge. But Professor MacFarlane stresses that creating sustainable fertiliser is the priority.

“We don’t want food versus fuel as an ugly, competitive nexus,” he says. “Fortunately, the economic value of ammonia for fertilisers is much greater than as a fuel.

“Most of us on this planet are here today because of fertilisers. Most of us like to think of ourselves as terribly organic, but 70 per cent of all the nitrogen compounds in our bodies have come ultimately from the Haber-Bosch factory. Haber-Bosch is also the name of the chemical process that makes ammonia for fertilisers. If the Haber-Bosch process hadn’t been discovered 100 years ago, this planet could not support the population that it does today.”

Ammonia can also make a versatile fuel. “You can run a vehicle on it, you can run a gas turbine on it, you could basically burn it and cook on it. So ammonia could well be the fuel of the future. It is easily transportable. Much more easily than LNG – liquefying ammonia is vastly more simple than liquefying natural gas,” he says.

“There is also the issue of stranded energy – we talk about the renewable energy that could be produced in the middle of Australia or the far west. Solar and wind. But it is miles away from where most of us need it.” An advantage of sustainable ammonia is that it can easily be shipped to where it's needed most – to the east coast of Australia, or Tokyo, Shanghai or Seoul, he says.

Artificial photosynthesis techniques developed by Professor MacFarlane in the Australian Centre for Excellence in Electromaterials Science (ACES), including colleagues from the University of Wollongong, are already being used to make sustainable hydrogen from water by their spinoff company, AquaHydrex. The hydrogen is being added to the natural gas pipeline, but could also potentially be used directly as a fuel source for electric cars.

And ionic liquids will be an important ingredient in batteries that are potentially cheaper, safer and more powerful than existing lithium batteries. Professor MacFarlane says flow batteries are also of great immediate interest for large scale grid-storage: “We have something we are about to patent, and are putting that forward right now.”

He explains that a flow battery functions like a traditional battery, “except that the liquid flows through the operating part of the cell from one tank to another tank. If you want more energy you get a bigger tank. It is an important concept for storing large amounts of energy.” The newly installed Tesla battery in South Australia “is a very, very big collection of very small batteries”, he says. “With a flow battery you simply have a larger amount of the active material that you flow through the battery.”

Other potential uses include:

Bio-compatible ionic liquids

Professor MacFarlane insists he is only a small player in the ambitious global effort to preserve coral reefs by creating frozen coral ‘seed banks’. In Australia, a coral cryopreservation bank with specimens from the Great Barrier Reef has been set up at Dubbo’s Taronga Western Plains Zoo. His biocompatible ionic liquids can also be used to preserve therapeutic proteins. For example, researchers have long known that the protein Interleukin-2 attacks skin cancer cells, but they have not known how to keep the protein alive out of the lab. Ionic liquids have been found that will preserve Interleukin-2 for up to two years. It is hoped a topical ointment will be developed from the discovery.

Green chemistry

Ionic liquids are also useful chemical solvents, and can be used to extract bioactive chemicals from food waste or biomass. “A lot of our drugs and pharmaceutical compounds come from, ultimately, crude oil,” says Professor MacFarlane. “A target for the future is a bio-refinery – what goes in is plant material and what comes out is bioactive materials, like antioxidants and other useful compounds, that nature has made.”